Copper Plating Contribute to RF Board Design

In RF (radio frequency) circuit board manufacturing, copper plating is one of the most important processes used. The material offers a variety of benefits to the finished product that help to improve performance, protect solderable surfaces, reduce resistance and impedance, provide conductive paths for signal transmissions and even increase corrosion resistance.

When designing a new RF PCB, it’s important to consider all of the different material and plating options available. Each plating process has its own advantages and can affect the final cost of the finished product. When choosing a material for your design, you must choose a material that meets the requirements of both your budget and the functionality of the final product. To help you with this process, our engineers will review all of your material and plating options including copper weights when performing DFM, leading to the RF design that best suits your project’s specifications.

The first thing to consider is the conductivity of the copper and its ability to transmit a high-frequency electrical current. The only metal that is more effective at conducting electricity than copper is silver, which can be very expensive to use for PCB conductors and traces. Luckily, copper is much more affordable and still offers excellent conductivity to your rf board.

Another benefit of copper is its malleability. Being a soft metal, it’s easy to apply to objects that require some flexibility and it won’t peel out of the material like many other platings do. Copper is also highly adhesive, meaning that it won’t separate from the object even under stress. This makes it perfect for applications that require a conductive surface that can also be soldered.

How Does Copper Plating Contribute to RF Board Design?

It also offers a decent level of corrosion resistance and is able to resist oxidation when exposed to air. In fact, copper plating is often used as a base coat for other more hardwearing materials such as nickel and silver. In this way, the plated layer is able to serve as a type of lubricant in high-temperature environments.

Lastly, copper is a very versatile plating material and can be used in both decorative and functional ways. Decorative copper plating is used to create a steampunk look on metal parts or can be anodized to achieve an array of colours. Similarly, copper plated components are sometimes used as a form of insulation on high-voltage wiring, especially in industrial environments.

Lastly, copper plating is compatible with most other coating and plating processes making it ideal for those who want to use their finished products in harsh conditions. It is particularly useful as a dual system with other metals such as nickel, tin and aluminium because it allows those additional processes to bond with the substrate with greater ease. For these reasons, we regularly use copper in conjunction with nickel and silver plating to ensure a high wear and corrosion resistant finish for our customers’ PCBs.

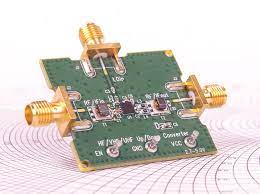

Radio Frequency (RF) Printed Circuit Boards (PCBs) are crucial components in a wide range of applications, from telecommunications and aerospace to medical devices and consumer electronics. The reliability of RF PCBs is essential to ensure consistent performance and longevity under various operational conditions. Several factors contribute to the reliability of RF PCBs, each playing a vital role in their overall performance.