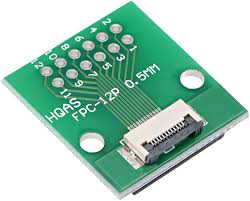

Flexible Printed Circuit Board

A flexible printed circuit board (FPC) is a type of PCB that’s characterized by its flexibility. It is commonly used in small electronics, such as laptops, smartphones, and tablets. FPCs are more durable than their rigid counterparts, and they can withstand bending without breaking. They also offer better heat dissipation than their rigid counterparts, which can help prolong the lifespan of the electronics in which they are used.

Unlike rigid PCBs, which are made of a single layer of insulating material and conductive copper, an FPC is typically comprised of multiple layers. The number of layers varies depending on the complexity of the circuit, but most FPCs have between 4 and 8 layers. However, some mobile devices have up to 12 layers.

To create an fpc circuit board, manufacturers print conductive lines on a thin film that’s either copper or polyimide. They then laminate the layer with insulating material onto a substrate, such as glass or polycarbonate. They use the insulating material to separate the conductive traces from one another, while leaving plated through holes for connection purposes.

What Is a Flexible Printed Circuit Board?

An FPC can have a single-sided or double-sided design. In the former case, the conductive traces are printed on both sides of the circuit board, while in the latter, they’re only printed on one side. It’s important to note that the multi-layer FPC is usually thicker than the single-layered one, which helps it withstand indelicate handling and last longer. Multi-layer FPCs also have more space for connecting components, so they’re suitable for power-intensive devices that need a higher capacity for efficient operation.

The multi-layer FPC is a popular choice for electronic products, and it’s easier to create prototypes with it than the rigid-type one. This is because the process of creating a multi-layer flexible PCB is less complex and easier on the equipment. Additionally, it allows manufacturers to reduce the size of their end products and improve their weight per volume.

The FPC’s durability and flexibility make it an ideal choice for a wide range of applications. Moreover, it has the potential to improve the appearance of end products by eliminating the need for connectors and terminals. This can save production costs, reduce the risk of damage to the product, and ensure that the product looks clean and elegant.

The demand for flexible electronics is growing, driving advancements in FPC technology. Innovations such as stretchable circuits, which can expand and contract, and the integration of FPCs with other emerging technologies like flexible displays and wearable sensors, are on the horizon. These developments promise to further expand the applications and capabilities of FPC boards, solidifying their role in the future of electronic design and manufacturing.

This is important, especially for consumer electronics, where appearance plays a major role in customer perceptions of the brand’s quality. Moreover, an FPC can make it easier to connect and disconnect components, which can lead to faster repairs and upgrades. This is because the manufacturer can reconnect cables by removing the FPC instead of having to disassemble the product. Besides, the FPC can be printed with different color schemes to match the appearance of the product.