Bonding Flexible Circuits

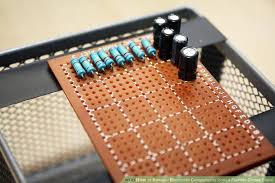

Whether you’re building a flexible circuit or a rigid-flex board, there are some common adhesive systems used throughout the stack-up. These include main material laminate and copper bonding, coverlay adhesion, and adhesion between layers in multilayer flexible designs. In addition, some flex circuits require reinforcements that help to ensure the structural integrity of the entire design. Adhesives are also employed to securely bond these reinforcements to the circuit boards.

The type of adhesives you choose for your flexible circuit PCB will depend on the operating conditions, substrate materials, and electrical/mechanical properties. To make the right decision, it is important to consult with your flex circuit manufacturer. They can provide recommendations and referrals for the best adhesive systems for your specific application and operating environment.

A specialized type of adhesive, known as FPC bonding adhesive or FR-4 adhesive, is often utilized for bonding the various components of a flex circuit. These adhesives are designed to maintain their flexibility and durability even when subjected to repeated flexing. In addition, they can withstand varying temperatures and environmental conditions.

Types of Adhesives Used in Bonding Flexible Circuits

There are a variety of different types of FPC bonding adhesives, and each one serves its own unique purpose. For example, there are thermosetting adhesives that can withstand high temperatures and stresses, while epoxy-based adhesives offer excellent bonding strength and durability.

These specialized adhesives can be used to bond the copper foil layer to insulating substrates, ensuring that the conductive paths are properly bonded to the underlying circuit material. They can also be used to secure coverlay materials, and they can be employed to bond rigid caps to the inner layers of a flex circuit. In addition, these specialized adhesives can be used to affix a flex circuit to a stiffener.

Another type of special adhesives that is frequently used in bonding flexible circuits are pressure sensitive adhesives. These are similar to double-sided tape, in that they have an adhesive on one side and a release film on the other. They are very easy to work with, and they show excellent bond stamina. They can also withstand a high temperature for short adventures, which is essential for certain applications.

Finally, there are flexible thermosetting adhesives that are commonly employed in the fabrication of flex circuits. These adhesives use a flexible polyimide core to laminate copper layers onto the base material, and they are used in multilayer flexible designs. They can also be used to bind the inner layers together in rigid-flex circuits, and they are sometimes used to bond a flex circuit to a stiffener.

Whatever type of flex circuit adhesive you use, it is crucial to understand its performance capabilities. You can do this by reviewing the data sheets and technical specifications for each product. By doing so, you can determine which system will meet the demands of your particular application. This will help to ensure that your flex circuit performs well in its intended environment without exhibiting any significant problems. By following this simple guide, you can make the right choice and ensure that your flex circuit is reliable and durable.